David Bruneel is a laser engineer and works at the R&D department of LASEA. This Belgian company which specialises in the production of laser micromachining systems, is a partner of the H2020 project Laser4Surf. David Bruneel talked with the European Science Communication Institute (ESCI) about shaping metal surfaces with nanosized structures and the market potential for such surfaces.

What is your research focused on?

Bruneel: We do a lot of work regarding laser-matter interaction to understand better how it works. We focus our work and our knowledge on applications to improve our systems and to become more competitive.

You can treat metal surfaces with the laser. Why would anyone do that?

Bruneel: Well, there are many applications. One of our main applications is micromachining in the watch industry, where we have to be able to treat different kinds of metals. But not only metals. We can also treat dielectric materials like sapphire glass or a lot of ceramic materials. Thanks to our technology we can treat more or less any material. We use mainly femtosecond lasers. “Femtosecond” refers to the pulse duration, and it is so short that it has a very specific way of interacting with the matter. This allows us to treat almost any material, even diamonds.

Would you say the femtosecond laser is indispensable?

Bruneel: I think one important point in this project is to use what we call ultrashort pulse lasers. That can be femtoseconds or picoseconds. Maybe we could also work with pulse durations that are a bit longer, like nanoseconds, but we are sure to get the best results by using ultrashort pulse lasers in this project.

What are the real advantages of these lasers?

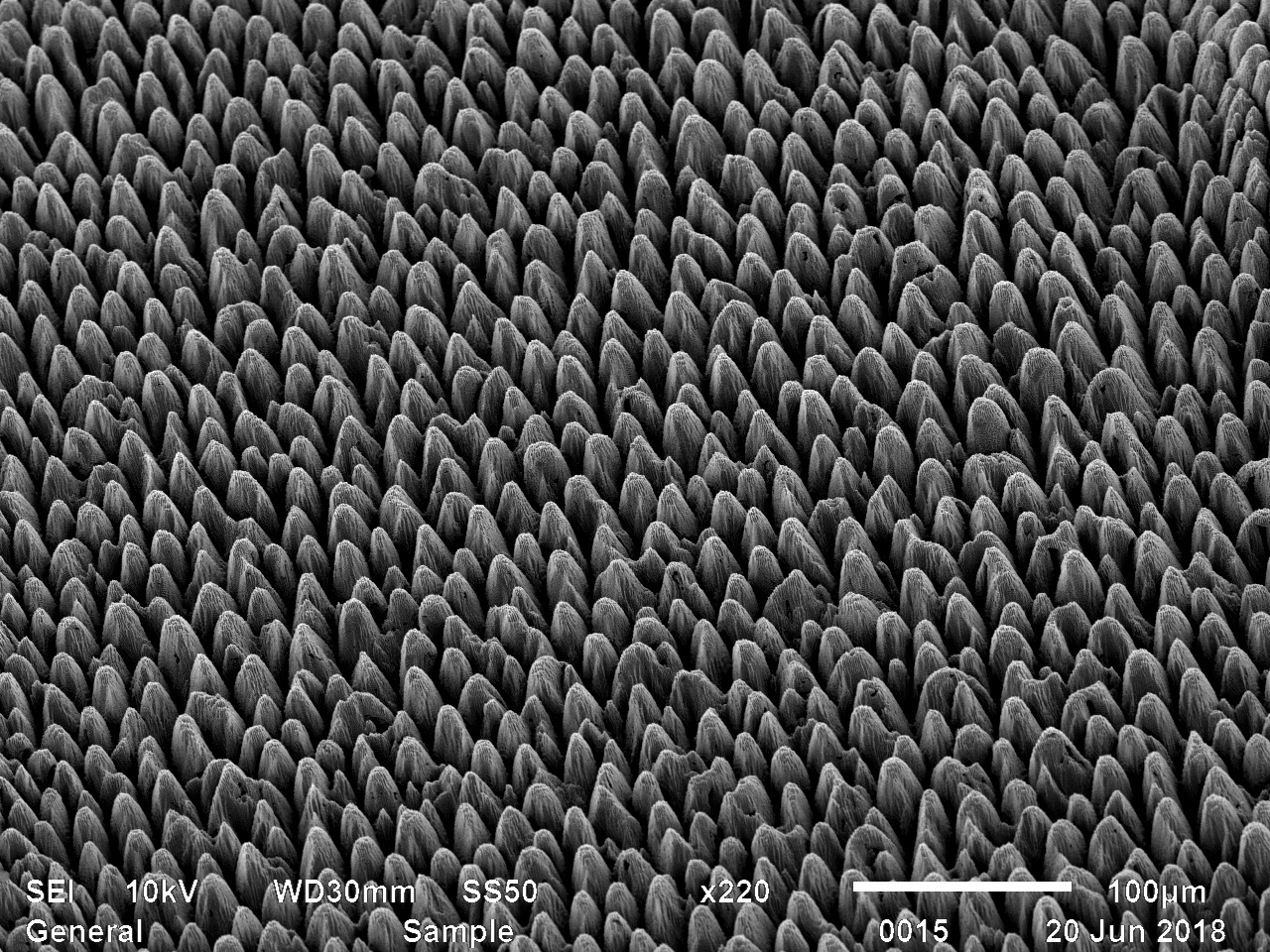

Bruneel: The real advantage of such short pulses is that there are almost no thermal effects, which enables us to do micro-machining. We have almost no heating of the material, so we can reach sizes and accuracy down to the micron or even further below. We can machine the metal; we can machine dielectrics. There is a lot of research on the process itself, because depending on the material, the process can be completely different. But at the end we can reach a very high quality thanks to this technology. For example, if we use a longer pulse laser, like a nanosecond or millisecond laser, we will have for sure thermal effects and we would not reach such high accuracy on the parts. Whereas with femtoseconds we have no debris, no burrs. It is really very nice technology.

What is the biggest challenge ahead in the Laser4Surf project?

Bruneel: To be able to reach the specifications that are going to be defined during the coming months. One of the project’s goals is to be able to reach some micron-size features, which is very challenging. And to be able to control the process very accurately, to have compelling results.