Graphics

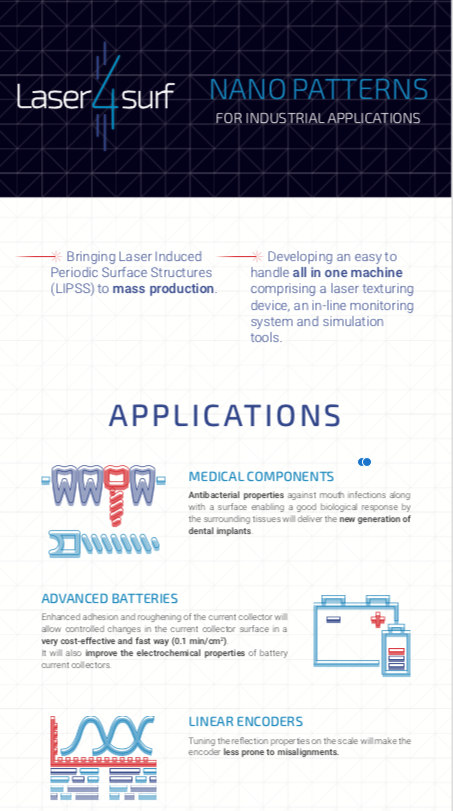

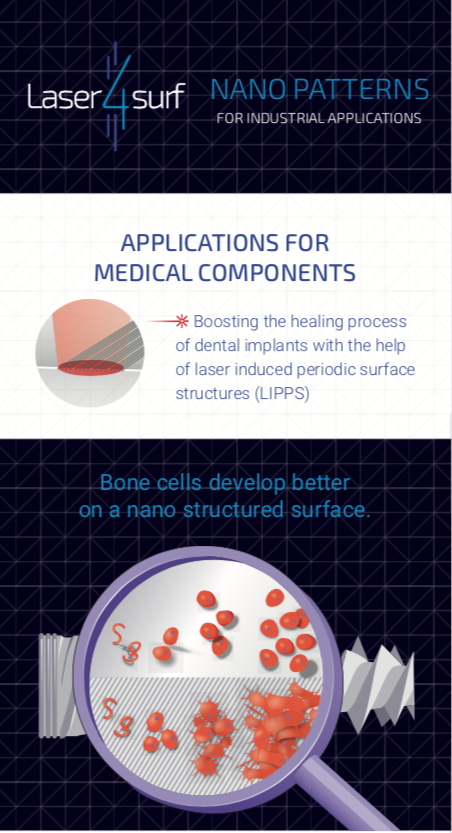

Final infographic

Public deliverables

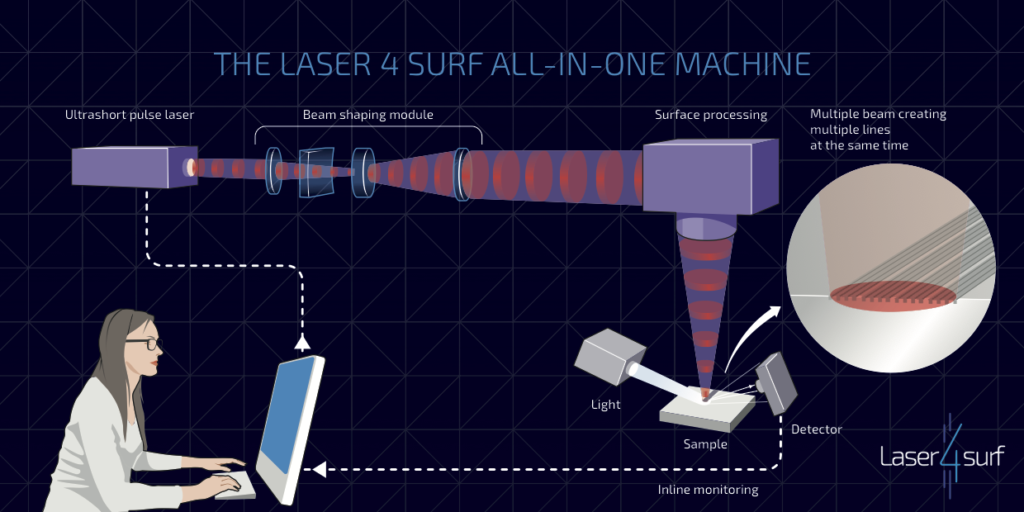

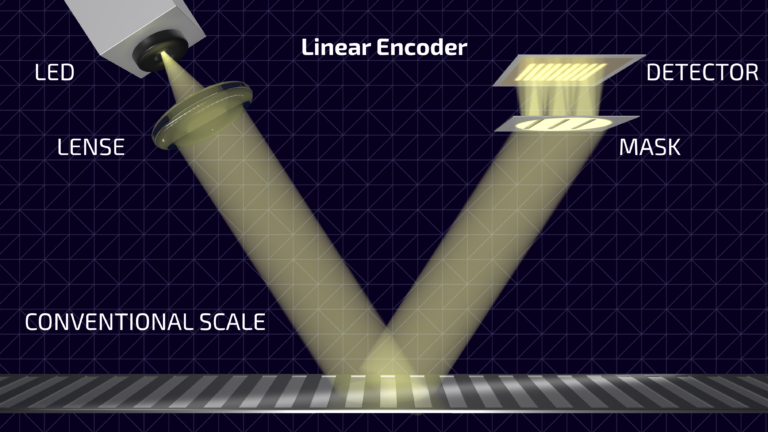

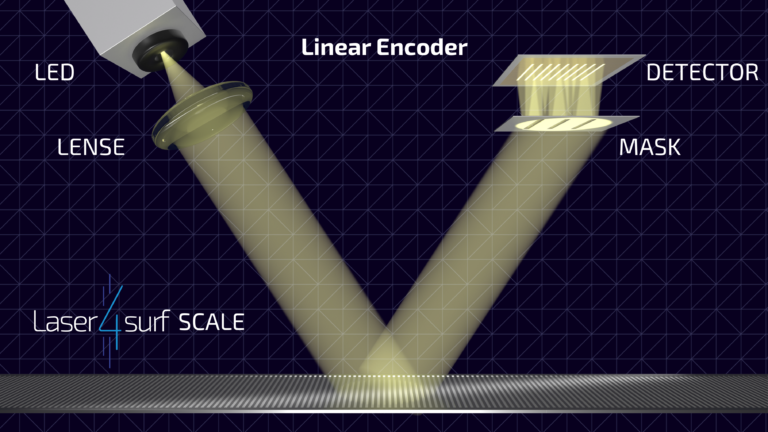

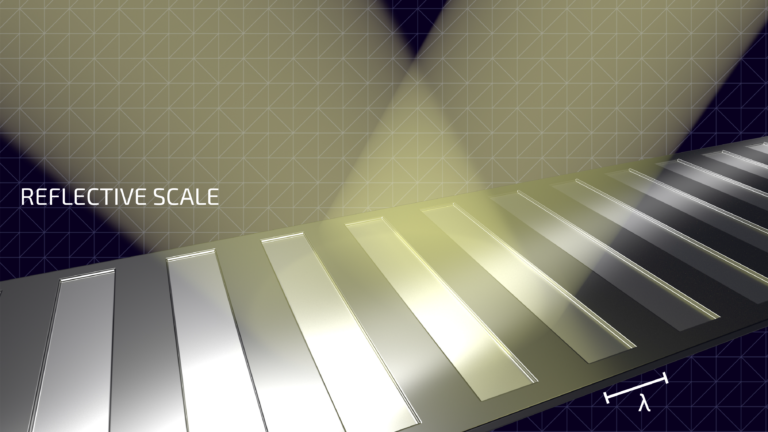

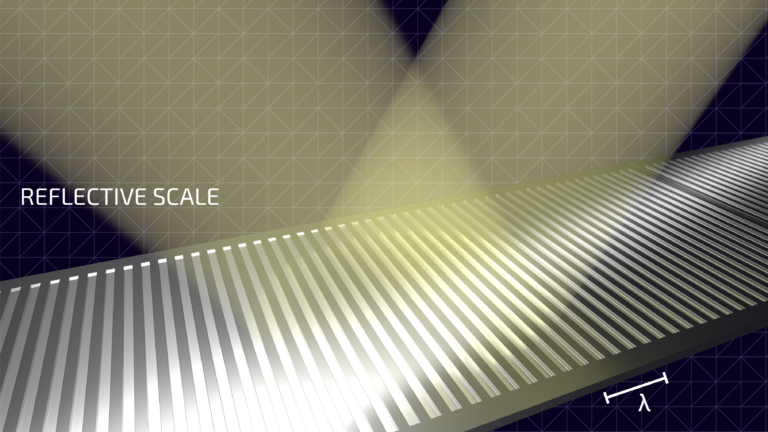

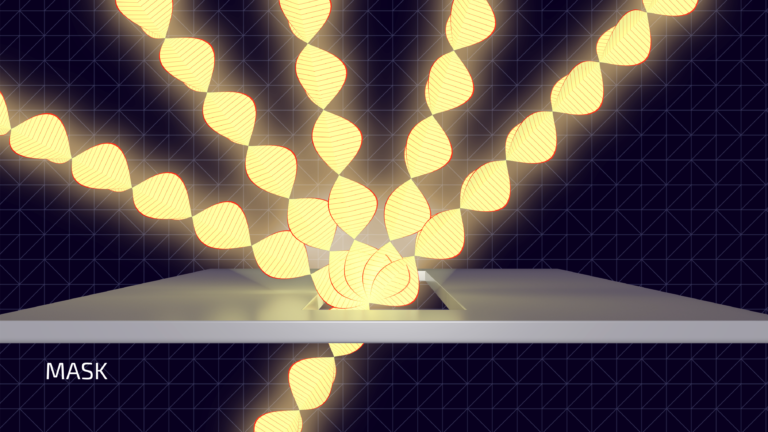

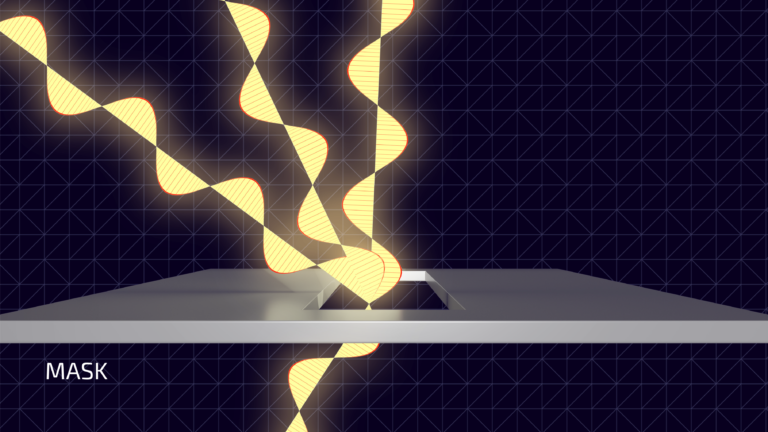

The project is expected to produce an introductory project video within the first four months of the project. The LASER4SURF introductory video is intended as a general presentation tool to be shown on the LASER4SURF website, at fairs, conferences or other relevant events and upon request. Targets for distribution are researchers and stakeholders at large. The LASER4SURF introductory video is aimed at informing relevant stakeholder communities of the general purpose of the project, its objectives, technologies used, targets and expected impacts deliverable.

Revelation of the Laser4Surf Prototype

Scientific publications

Micro-structuring of gold coated plates with LIPSS for localized plasmonic sensors

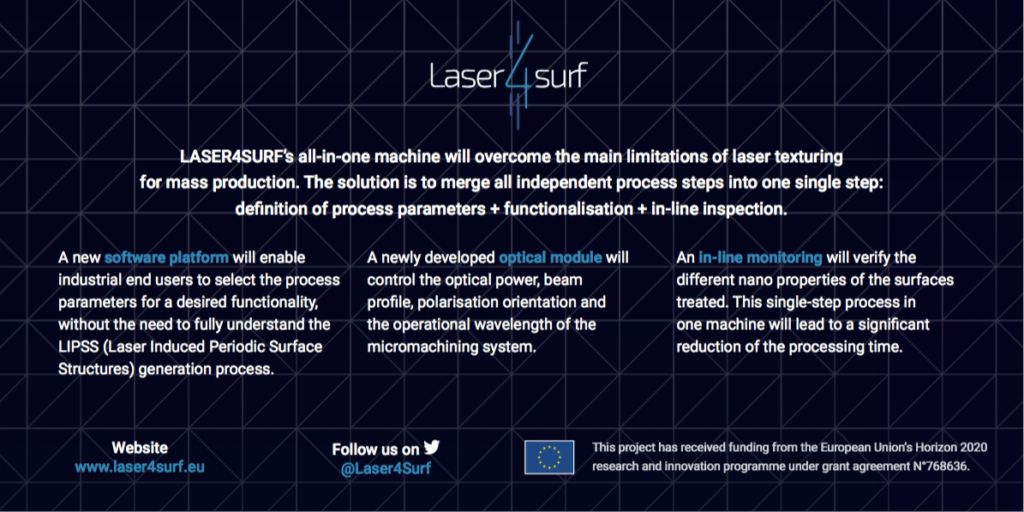

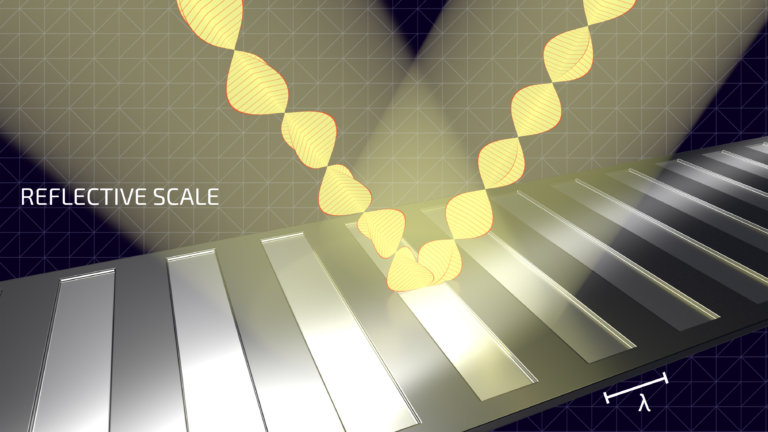

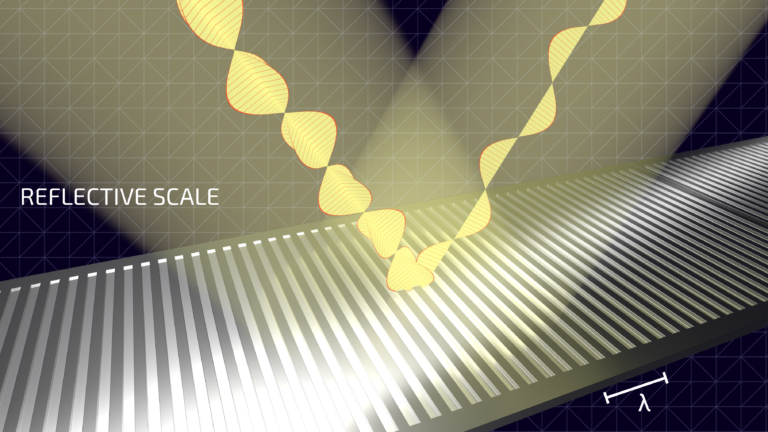

We investigate Laser Induced Periodic Surface Structuring (LIPSS) in order to produce sub micron periodic patterns on gold layer for localized plasmonic sensors fabrication. LIPSS are peri-odic structures that are generally created on a material surface by accumulation of ultra-short pulses exhibiting energies close to the material ablation threshold. Although LIPSS physical mechanisms are still under investigation, they have been induced in a wide variety of materials (metals, semicon-ductors, polymers, etc) for numerous applications such as realization of hydrophobic/hydrophilic surfaces, control of surface reflection or realization of low friction / high adhesion surfaces. Here we used ultrashort pulses (500 fs) at 515 nm to induce LIPSS structures on thin gold layers for LSPR sensors.

To read full paper, please click on image to the left.

Beam Shaping and Power Handling of an Spatial Light Modulator system for Laser Induced Periodic Surface Structuring Texturation

Laser Induced Periodic Surface Structuring(LIPSS)is a powerful toolfor creating sub-micrometric features on large surfaces in an up-scalable and industrial way. In order to control the process and reach a sufficient uniformity for some applications a careful attention must be paid to the control of the laser beam parameters likeits polarization, stability and shape. A uniform beam shape is mandatory in some cases. Although some demonstrationsof beam shapingwithhigh power handlingoptical components have been made, there is not much reported regarding the use of SLM(Spatial Light Modulator)for beam shaping of ultrashort pulses. In the current work we show the possibility to use SLM with different type oflaser sources, including a femtosecond system deliver-ingup to 1 mJ per pulses.

To read full paper, please click on image to the left.

Femtosecond laser fabrication of LIPSS-based waveplates on metallic surfaces

To read full paper, please click on image to the left.

Tailored femtosecond laser fabrication of reflective waveplates

San-Blas, Alejandro; Casquero, Noemi; Martinez-Calderon, Miguel; Buencuerpo, Jeronimo; Sanchez-Brea, Luis Miguel; del-Hoyo, J; Olaizola, Santiago Miguel; Rodriguez, Ainara; Gomez-Aranzadi, Mikel

Laser induced periodic surface structures (LIPSS) can be studied as waveplates due to the birefringence induced by the nanoripples, with easy fabrication since they are fabricated in a one-step process by laser, where LIPSS geometry are defined by the characteristics of the laser and the substrate. The optical properties of these waveplates are defined by LIPSS parameters such as period, depth or width of the ripples. In this work we have measured the change in polarization of the light reflected from LIPSS generated on stainless steel. Results show a gradual change in polarization as the parameters employed in the fabrication vary. As shown in our experiments with a setup based in cylindrical focusing lens, the fast fabrication of samples with applications as waveplates is demonstrated.

Proceedings of LiM 2019

To read full paper, please click on image to the left.

Innovative method to enhance the control over the fabrication of LIPSS on metallic surfaces

Gomez-Aranzadi, Mikel; Casquero, Noemi; Martinez-Caldero, Miguel; San-Blas, Alejandro; Olaizola, Santiago Miguel; Rodriguez, Ainara

LIPSS are an emergent method of fabricating functional surfaces. A high repetition rate ultrashort pulsed laser was used to generate LIPSS on metallic surfaces. Different combinations of the processing parameters were tested to study their effect on the period of the LIPSS. Additionally, the influence of the repetition rate (laser frequency) on the LIPSS period was also studied when the same number of pulses, polarization and peak fluences are applied. Finally, a chemical analysis was performed in order to establish a correlation between the laser processing conditions and the resulting chemical modifications (especially oxidation) in the ultrashort pulse regime. As expected, the analysis shows a decrease in the period of the LIPSS as the number of pulses increases, while the other processing parameters affect the period slightly. Regarding the laser frequency, variations in the repetition rate –while the rest of the parameters are kept constant- only slightly affect the period and morphology of the LIPSS. In the case of the chemical variations, two different regimes were found, with Low Spatial Frequency LIPSS exhibiting no oxidation for low accumulated fluences and High Spatial Frequency LIPSS presenting increased oxidation as the fluences accumulate.

Proceedings of Lasers in Manufacturing 2019

To read full paper, please click on image to the left.

MONITORING INNOVATION: Optical systems to support the production of surfaces with advanced functionalities.

Elodie Bugnicourt, Severine Philippe, Tim Kehoe, Laura Rodriguez, Simona Neri

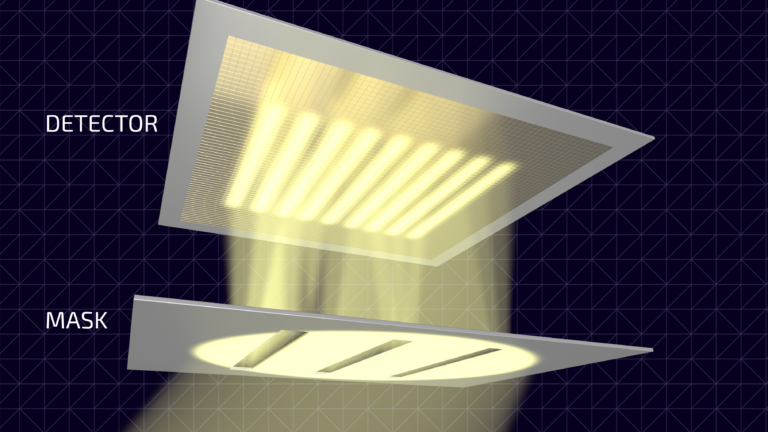

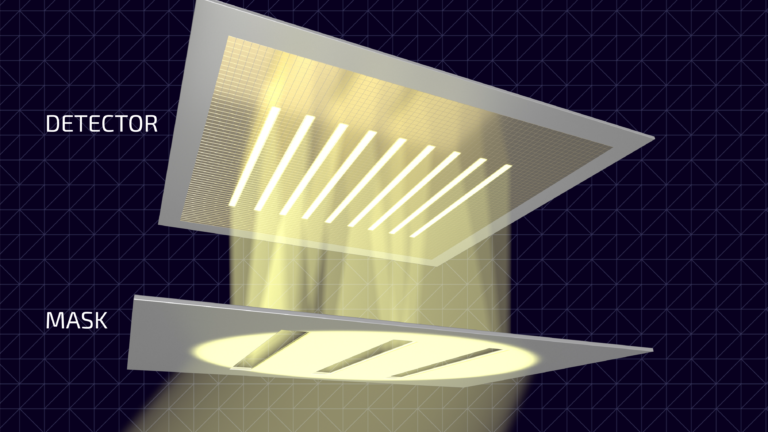

Enhanced product performance through fine surface function-alisation requires process control beyond standard metrologi-cal practice. One of the first steps to digitalisation, and Indus-try 4.0, is inline monitoring using in-process sensors. In line with the progresses of photonic technologies, novel systems have proven effective for real-time detection of defects, devia-tions, or other anomaly and potentially to instigate corrective actions, thanks to modelling resulting in optimal quality and scrap mimisation among other benefits.

To read full paper, please click on image to the left.

Fabrication of tuned LIPSS-based metallic polarization gratings

A. San Blas; N. Casquero; M. Martínez-Calderón; J. Buencuerpo; L. M. Sanchez-Brea; J. del Hoyo; S. M. Olaizola; A. Rodríguez; M. Gómez-Aranzadi

Surface nanostructuring has received increasing attention in recent years due to the wide range of applications in which it offers advantages. Particularly, Laser-Induced Periodic Surface Structures (LIPSS) have proven useful for surface functionalization [1]. LIPSS are periodic formations generated in most materials when irradiated with linearly polarized radiation. The orientation of these structures is directly linked to the polarization of the incident light, while other parameters of their morphology such as period and depth can be controlled with the number of pulses, fluence, wavelength and pulse duration of the incident light.

The paper can be purchased under 10.1109/CLEOE-EQEC.2019.8872189

Fabrication of LIPSS-based metallic polarization gratings

San Blas, Alejandro; Rodriguez, Ainara; Casquero, Noemi; Olaizola, Santiago Miguel; Martinez-Calderon, Miguel; Gomez-Aranzadi, Mikel

Birefringence induced by nanoripples generated by laser (Laser Induced Periodic Surface Structures, LIPSS), enables their use as polarization gratings. Their fabrication is simple, as LIPSS geometry is defined by the characteristics of the laser and the substrate in a one-step process. In this work LIPPS generated on stainless steel have been used to measure the change in polarization of the light reflected on them. Parameters such as period, depth or width of the ripples define the optical properties of these polarization gratings. As the fabrication parameters change, results show a gradual change in polarization. Our experiments, performed with a setup based in cylindrical focusing lens, demonstrate the fast fabrication of samples for different applications, such as waveplates.

Proceedings of LAMP 2019

To read full paper, please click on image to the left.

Polarization conversion on noanostructured metallic surfaces fabricated by LIPSS

Alejandro SAN-BLAS, Noemí CASQUERO, N. PÉREZ, M. MMARTINEZ-CALDERON, Luis Miguel SÁNCHEZ-BREA, Jerónimo BUENCUERPO, Santiago Miguel OLAIZOLA, Ainara RODRÍGUEZ

The paper can be purchased under https://doi.org/10.1117/12.2506982

Burst picosecond hybrid fiber/crystal laser for LIPSS processing

Polarization conversion on nanostructured metallic surfaces fabricated by LIPSS

Casquero, Noemi; Martinez-Calderon, Miguel; Perez, Noemi; Granados, Eduardo; Olaizola, Santiago M.; Rodriguez, Ainara

Fabricating reflective waveplates using nanostructured surfaces has taken great interest in recent years due to their simple structure: a diffractive grating composed of ripples with subwavelength period. The surface ripples act as an artificial birefringent material: the anisotropy of the surface corrugation generates a phase delay between two perpendicular light polarizations. The control of the period, fill factor, depth and orientation of the ripples are crucial to optimize the change of the polarization of the reflected light. Although there are different strategies to fabricate subwavelength diffraction gratings to convert the polarization of light in reflection mode, here we propose the use of Laser Induced Periodic Surface Structures (LIPSS) as a new approach for this purpose. In this work, large area subwavelength reflective gratings have been fabricated via LIPSS with periods of 580 nm and 630 nm. These gratings were able to convert the incident linear polarized laser light at 633 nm into reflected circular polarized light, and vice versa, with ellipticity values lower than 2,7°. This is, to the best of our knowledge, the first report on the use of LIPSS for polarization conversion.

Conference proceeding of the work presented in LPM2018

To read full paper, please click on image to the left.

Tailoring birefringence of LIPSS through thin film coatings

San Blas, Alejandro; Casquero, Noemi; Sanchez, Sergio; Sanchez-Brea, Luis Miguel; Buencuerpo, Jerónimo; Rodriguez, Ainara; Olaizola, Santiago M.

Waveplates modify polarization by generating a phase change. Laser Induced Periodic Surface Structures (LIPSS) have recently started to be studied as waveplates due to the birefringence induced by the nanoripples, easily fabricated in a one-step process by laser, where LIPSS morphology is defined by the characteristics of the laser process parameters and the substrate material. The optical properties of these waveplates are defined by LIPSS parameters such as period, depth or width of the ripples. In this work we have deposited thin film coatings on stainless steel samples containing LIPSS for different coating thickness and composition. Results show that thin film coatings are a good candidate for the tunability of LIPSS birefringence since the coating modifies the induced polarization change and reflectivity of the sample depending on coating thickness and composition, as expected from numerical simulations.

Conference proceeding of the work presented in LPM 2018

To read full paper, please click on image to the left.