The main pillar of a sustainable future is a reliable energy system using renewable sources. One of the biggest challenges in reaching this aim is energy storage. Ultra-fast laser pulses are now used to improve today’s rechargeable Li-ion batteries, resulting in an increase of the electrode’s capacity by up to 60% and a lifetime extended by 30%! Physicist Dr. Miguel Ángel Muñoz-Márquez is group leader of Advanced Interface Analysis at CIC energiGUNE in Álava, Spain and he specialises in battery research. He explains why laser surface treatment is the key to sustainable batteries.

In the EU-funded research project Laser4Surf you are working on a laser treatment to modify surfaces of battery components. Which components are you focusing on and why will that improve our batteries?

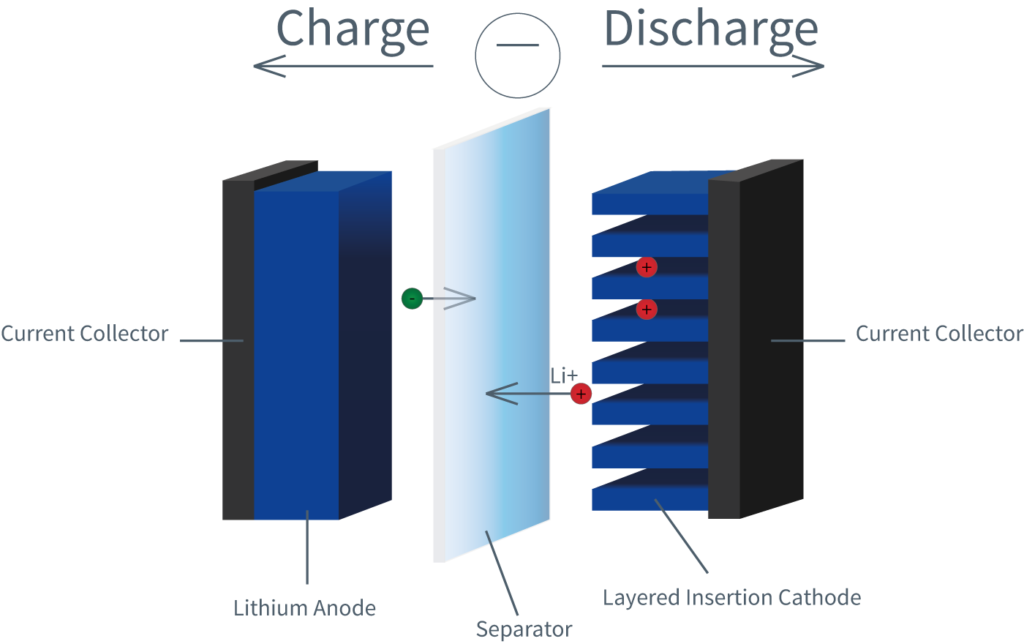

Muñoz-Márquez: Batteries have three main components: the positive part – the cathode – the negative part called anode, and in between them, you have the electrolyte. To get the current out of the battery, the cathode and anode need to be electrically connected to the external circuit. This connection is mediated by the current collector which is a metal, typically aluminium and copper in Li-ion batteries. We now aim to modify the surface of this metal in order to improve the adhesion and electrical contact of the cathode and anode in the battery. This extends the lifetime and the electrochemical properties of the battery. Basically, we try to make better batteries.

Better batteries for a better sustainable future?

Muñoz-Márquez: Yes. There are several factors to consider here. The challenge is that our dependence on fossil fuels is so strong that the only way to change that is to think about efficient energy storage systems, and with lithium-ion batteries we are almost there. In fact, the number of electric vehicles entering the market is increasing every day. But there is also the question about how the electricity is produced and managed on the grid. We need to improve efficiency. As we have a general shift away from fossil fuels, we need renewable sources of energy. These are random in nature. You cannot control the wind, the sun, the clouds. So, we need a system to fully control the energy produced and fed into our grids – batteries are the key issue here. With batteries you can regulate the frequency, the overproduction, the lack of production and you can level the grid.

Why do you think laser surface treatments are the key rather than changing components or design?

Muñoz-Márquez: Of course, it is a combination of everything. You have to continue working on new materials or new concepts. But, with this project, we are actually trying to go to a very critical issue – the lifetime. I mean, it´s OK if the battery in your mobile phone or laptop is not usable after three to four years – you can replace it and the cost is not very high. I would prefer not to do so, but you can accept that. In an electric car, the battery probably costs about 50% of the total price of the car; you don’t want to change the battery after four years. You need the battery lifetime to be in the region of 10 years. And for grid application, where batteries are even bigger and more expensive, you’re looking at 25 plus years of use. For this, we need to get a quick win.

How do you apply the laser technique and is it applicable to industry, so that we as consumers might really profit from your research?

Muñoz-Márquez: We want to modify and refine the surface of the current collector, so the contact is better, and no losses affect the battery performance. With the laser we can do this in a controlled and reproducible way, which is what the industry is looking for. We hope this will bring about a 30% increase of the lifetime of our current rechargeable lithium-ion batteries, which is the main focus in this project. Additionally, the modified surface of the current collector leads to an improvement in the velocity of electron exchange. This means that you get a fast response from your battery – an increase in the velocity of charge and discharge. This is also a key point. Here you have a simple example: if you want to overtake or to slip onto a motorway quickly with an electric car, you can only get a fast response of your car if the battery can discharge very fast when you put the throttle down. Also, it is important that you can charge your car very fast, in about 15 minutes, which is a reasonable time. I do not want to have to wait eight hours in the middle of nowhere to charge my car.