Be it for machine tools or solar plants, Dr Aitor Olarra has spent nearly two decades developing the encoders that determine positioning performance. Here he tells Laser4surf how he developed test-benches to calibrate these devices, so very critical to motion control.

You worked at IK4-TEKNIKER for more than 18 years – what have been your key developments?

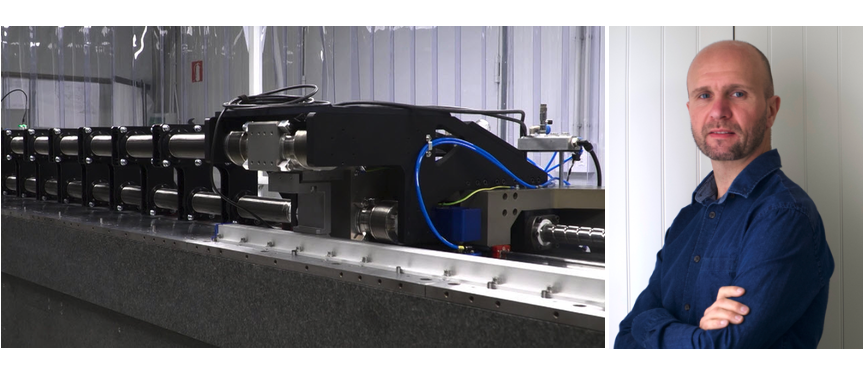

Olarra: My main developments related to assessing and enhancing the positioning performance of many devices including encoders, which provide direct position feedback to a range of machine tool and automation systems. Together, my colleagues and I developed powerful linear and angle encoder calibration benches for nanometric calibration and measuring systems. These help us to understand the behaviour of the encoders under different working conditions, so we can optimise the performance of industrial machines such as high-output lathes and machining centres. The test benches can achieve unprecedented measurement accuracy down to 10nm/m and our partner, Fagor Automation, has used these instruments to identify subtle performance details to improve its own encoders. Importantly, the benches also provide direct traceability of results to the International System of Units (SI), and are specifically designed to enable much shorter measurement times than the general purpose benches available at the National Metrology Institutes.

Have you an example of how the benches have enhanced encoder performance?

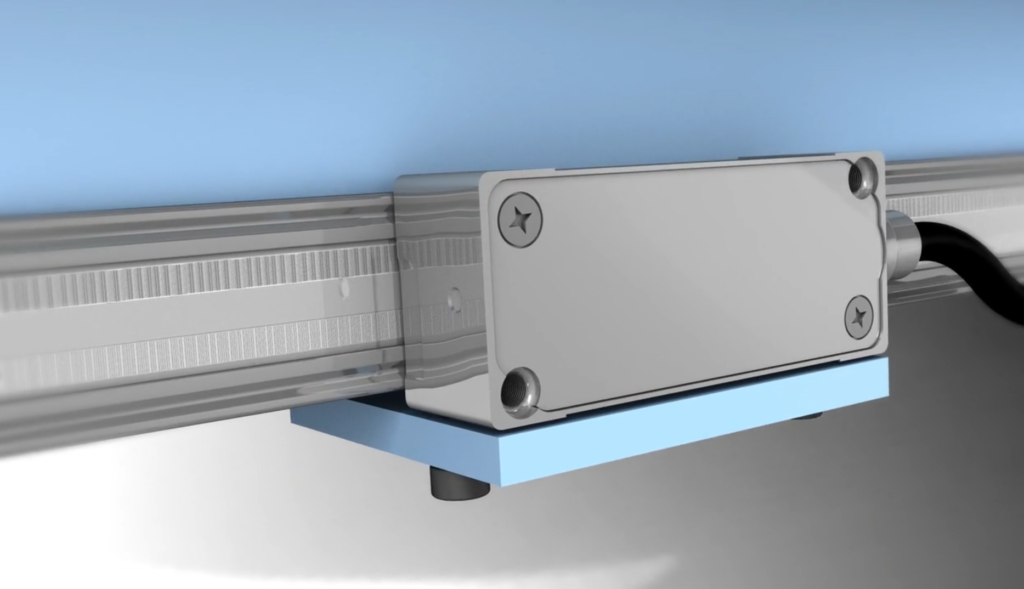

Olarra: The calibration benches have been used to reduce interpolation errors, a key issue in precision metrology. Optical encoders provide direct position feedback to various machine tool and automation systems and rely on periodic gratings – marks engraved into glass or metallic surfaces – to measure displacement. The encoder determines displacement by measuring how many marks have passed in front of its read head. To provide better resolution than the grating period, the read head interpolates the output signal from a period of the grating, but this can introduce errors. However, thanks to their high resolution and accuracy, the test benches can identify the linearity errors typically associated with interpolation. Using such results, researchers at Fagor Automation have reduced interpolation errors by adapting the encoder’s reading head conditions and also by developing new processes to create the periodic gratings. Indeed, Laser4surf has already adopted such changes and generated gratings via different processes.

ESCI: What impact have your calibration benches had to date?

Dr Olarra: So far, the calibration benches for encoders have been very successful. Fagor Aotek – the research and development arm of Fagor Automation – is using the instruments to enhance its full range of encoder systems. The potential impact of these improvements is vast, as encoders are used in a huge range of products from the printers and scanners found in almost every office across the world to cutting-edge science projects such as large telescopes. It is actually very difficult to find a single device or process that does not use encoders to make movements or measurements of some kind.

ESCI: Is there anything novel about the way you developed the calibration benches?

Dr Olarra: The performance assessment of these benches is quite special. The precision of the instruments is so high that each provides an extremely low measurement uncertainty, comparable to that provided by the benches available at the National Metrology Institutes. However, this means that we cannot assess bench performance using the usual laboratory certified standards, so instead, we use a process called intercomparison. Here, measurements from calibration benches at different laboratories are compared so that it is possible to agree on a result and check whether the different results are compatible with the estimated uncertainty from each laboratory.

ESCI: Will the calibration benches be used in the Laser4surf project?

Dr Olarra: Yes, the encoders developed by Laser4surf partners will go ‘under the microscope’, with the calibration benches being used to better understand encoder performance, assembly tolerances and other application-specific details.

ESCI: Laser4surf is generating gratings in linear encoders a little differently to conventional methods – can you tell me how?

Dr Olarra: The gratings of linear encoders are typically created using a master grating, which is an accurately manufactured part that is used over and over again as part of a lithographic process to fabricate the final grating patterns in encoders. However, the master gratings wear during use and need to be replaced. In contrast, Laser4surf uses a program-controlled ultra-short pulse laser for surface texturing. This laser source can be used to repeatedly and reliably produce these grating features in an encoder in a simple, single-step process and without the need for a master grating. This approach has great potential in the production of custom products at low cost and in large quantities. To use an analogy, the conventional master grating is like a photographic negative that is used to produce photographs, and in time, will deteriorate. Meanwhile the Laser4surf process resembles a modern printer that swiftly produces photos without requiring negatives.

ESCI: How does the performance of a linear encoder fabricated via the Laser4surf process compares to a conventionally-manufactured linear encoder?

Dr Olarra: The Laser4surf process is new and it’s still going to take a lot of time and hard work to fabricate encoders with the same performance, in terms of scale, linearity and feature edge definition, as your classical encoder. But on the other hand, using this process, it is already possible to skip the difficulties relating to handling and the use of masters.

ESCI: Looking at the future of linear encoders, what are you excited about?

Dr Olarra: I have always been excited about enhancing the positioning accuracy of systems where it is not possible to directly measure the point of interest. Usually this is achieved through calibration on a model that resembles as accurately as possible the behaviour of the system. We have applied this approach to many machine tools, including hexapods and even heliostats. Optical encoder systems have been, and always will be, key elements in all kinds of motion control applications as they provide very high resolution and accuracy both at short and long measuring ranges.

ESCI: You recently left IK4-TEKNIKER and moved to Ulm in Germany – why?

Dr Olarra: I would like to learn about the German working culture while increasing the impact of my job, both as a researcher and as a developer of devices, in the field of precision engineering from machine tools to measurement devices. Germany-based companies are very successful in all technical fields and I believe I will have many opportunities here right now, I am also focused on learning the Deutsch language and in a few months’ time I would like to start working in a leading company.